Advantages

Easy to clean & finish

High strength & durability

good balance of properties between rigidity and functionality

superior chemical resistance

Ideal Applications

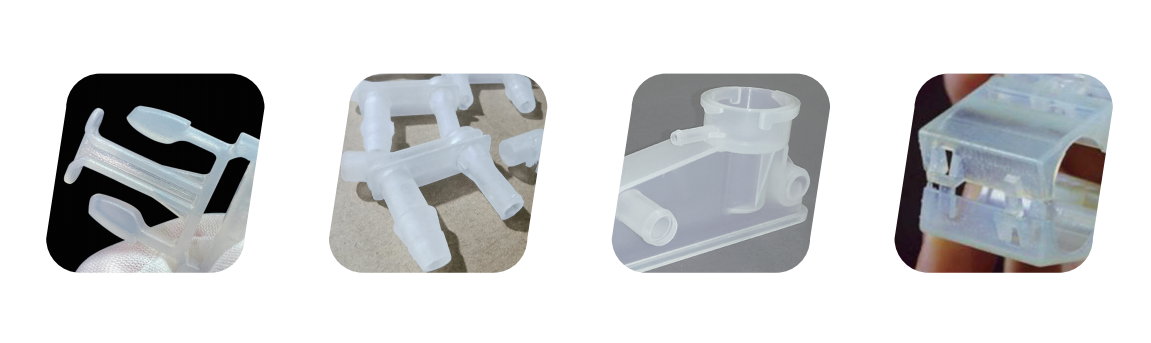

automobile components

electronic housings

medical products

large panels and snap-fit parts

Technical Data-sheet

| LiquiD Properties | OpTicAl Properties | |||

| Appearance | Off White | Dp | 5.6 mils | [slope of cure-depth vs. In (E) curve] |

| Viscosity | ~450 cps @ 30°C | Ec | 10.9 mJ/cm² | [critical exposure] |

| Density | ~1.13 g/cm3 @ 25°C | Building layer thickness | 0.08-0.012mm | |

| Mechanical properties |

UV Postcure |

polypropylene* | |||

| ASTM Method | Property Description | Metric | Imperial | Metric | Imperial |

| D638M | Tensile Strength | 30 - 32 MPa | 4.4 - 4.7 ksi | 31 - 37.2 MPa | 4.5 - 5.4 ksi |

| D638M | Elongation at Yield | 15 - 25% | 15 - 21% | 7 - 13% | 7 - 13% |

| D638M | Young’s Modulus | 1,227 - 1,462 MPa | 178 - 212 ksi | 1,138 - 1,551 MPa | 165 - 225 ksi |

| D790M | Flexural Strength | 44 - 46 MPa | 6.0 - 6.7 ksi | 41 - 55 MPa | 6.0 - 8.0 ksi |

| D790M | Flexural Modulus | 1,310 - 1,455 MPa | 190 - 210 ksi | 1,172 - 1,724 MPa | 170 - 250 ksi |

| D2240 | Hardness (Shore D) | 80 - 82 | 80 - 82 | N/A | N/A |

| D256A | Izod Impact (Notched) | 48 - 53 J/m | 0.9-1.0 ft-lb/in | 21 - 75 J/m | 0.4-1.4 ft-lb/in |

| D648-07 | Deflection Temperature | 52 - 61°C | 126 - 142°F | 107 - 121°C | 225 - 250°F |